The following is a contributed article by Peter Kirk, Business Operations Executive at GE Power Digital Solutions.

With all of the press that neural networks have been getting recently, you may be asking yourself, "What is a neural network, and should I be intrigued or scared?" A neural network is a form of artificial intelligence (AI) that is loosely modeled after the human brain, and it can help solve real-world problems in the energy sector and beyond. Whether it’s a threat or salvation depends on how it’s used.

In the 1990s, after the last AI hype cycle, a popular way to thumb one’s nose at AI was to point out that neural models could generate a 24-hour weather forecast that is more accurate than a meteorologist — it only takes 48 hours on a supercomputer to do so.

But over the past few years, AI and Machine Learning (ML) have become a potent force, not just because of their ability to process enormous amounts of data but also because they’re cheap. The impact is real — analyst firm Gartner estimates the global business value derived from AI will reach $3.9 trillion in 2022 — but we are also just beginning.

The promise of advanced analytics in the energy sector

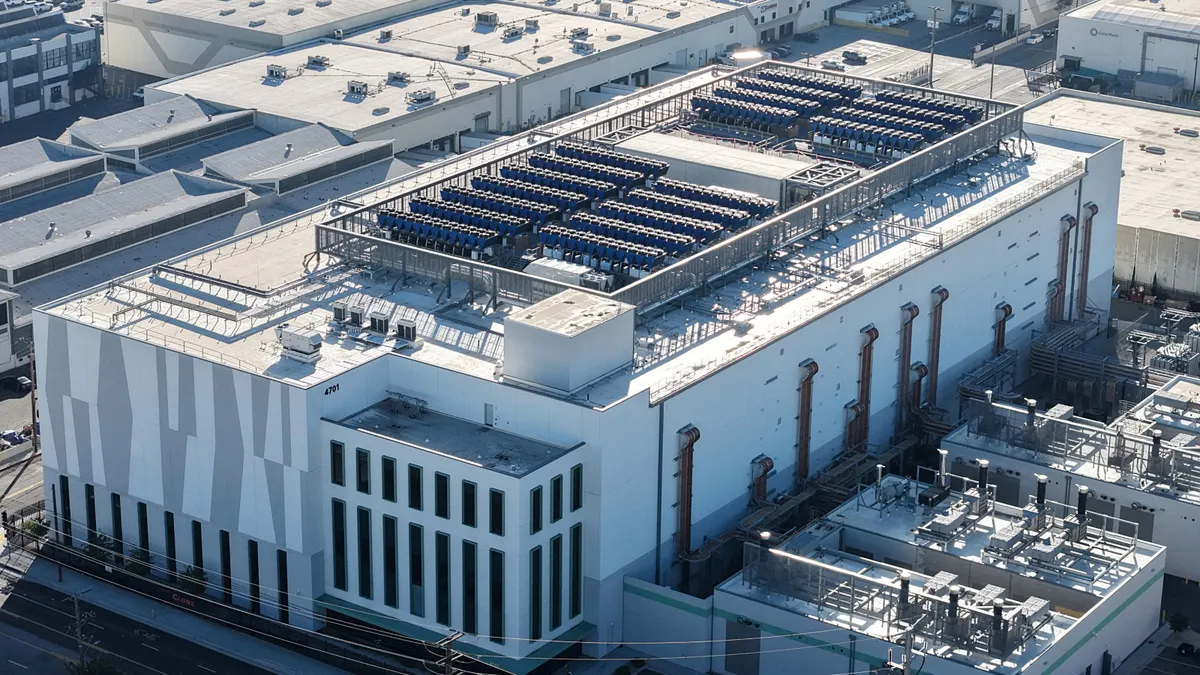

Currently, the entire power industry is leveraging only a small fraction of its data. It’s not that the data is unusable, but it requires very specific expertise to consume and gain insights. Overhyping AI/ML, particularly neural networks, fails to recognize how a versatile AI/ML platform integrated with domain expertise and focused on edge-to-Cloud applications can be. Such platforms are driving value today and are poised to drive a lot more in the future.

Recent advances in neural learning have moved whole new categories of value-add business applications, and utilities are recognizing the need to harness and leverage their data. According to a recent Accenture study of utilities executives, "99 percent believe that AI will be used routinely in decision support in the control room and in network planning by 2025."

But too much focus on neural risks leaves value on the table. I instead advocate for a "combined arms" approach, attained by applying a broad and integrated set of AI/ML techniques — neural, heuristics, first principles, multivariate predictive control, etc. — informed by human knowledge.

For more than 20 years, utilities have used solutions to take action on power plant floors — moving critical variables of core processes, environmental compliance and KPIs in all aspects of fossil generation.

Deep learning, a recent neural advance, leverages a utility’s data and external data to anticipate outages and deploy response teams to quickly restore power and predict when systems will need repairs. This approach in turn drives faster storm recovery and better personnel and inventory management and reduces cost.

These seemingly very different applications are supported by a common, robust, integrated, industrial AI/ML platform.

When does leveraging AI/ML make sense?

It’s important to consider what is needed from your people and your technology in order to create useful AI/ML applications. Often, a criticism is that neural is the second-best solution to every problem. But if that’s true, why is it also required for resolving complex industrial challenges?

Different technologies are useful for different challenges. You need a software platform that is flexible with respect to AI/ML techniques. You also need people adept at applying them and who understand industrial processes to answer two questions:

- What tradeoffs can the software manage or help a human manage to improve the KPIs for an asset or process?

- Can that benefit be delivered affordably?

Neural shines in the investigation phase. It ingests lots of data quickly, identifies linear and non-linear correlations, and (if you’re letting it) tweaks the process or asset when it "thinks" the tweak might help, or doesn’t know that it will hurt. It’s important to establish constraints; otherwise, AI will make tweaks you may not like. We frequently find ways to close the loop with neural models or ways to motivate human action based on what neural learns.

It is crucial to then critically assess whether the relationships neural identifies can be more reliably or precisely (where precision is important, as it isn’t always) described by an alternative. As a general rule of thumb, the more deterministic the alternative is, the better.

Think of it like building a stone wall to hold back a stream. The stones may fit almost just right to create a strong barrier, but to get all the way there, you need to use mortar. Sometimes, neural is the mortar. This development approach brings the right kind of solution to different aspects of a complex process or asset. It also allows neural to focus on the truly stochastic, data-rich aspects, in which neural is frequently the only affordable option in the long term.

The human element in AI/ML

Integrating human knowledge may be the most challenging aspect of applying AI/ML. Engineering and AI/ML seem like they should be an easy combination because they are in some ways "technical" and because any application that is appropriately constrained or which employs heuristics or first principal must be informed by domain experts. But the electrical or mechanical engineering pursuit of precision can lead to poor technology choices and demands on data completeness, precision and repeatability.

On the other hand, you would not want an AI/ML data scientist managing an outage, either. An industrial AI/ML expert is yet a third persona, blending domain expertise with AI/ML expertise. That human resource is rare, but it enables us to critically examine a process or asset and recommend whether the operations could be significantly improved by investing in advanced controls, or whether standing pat comes at no significant KPI penalty.

Investing in advanced controls – Is it worth It?

Getting inside the control layer, in compliance with NERC critical infrastructure protection or similar rules, has two big benefits for cloud-based analytics. First, there is a lot of value that can be created at a site by allowing machines to directly influence some processes or assets and analyze and suggest action in others. For example, let a boiler optimizer application distribute fuel and air, clean surfaces and tell you when the recent coal change put your rolling 30-day NOx mandate at risk. Or, let an anomalous consumption detector tell you that a particular substation is not going to behave as it has in the past.

Another benefit of optimization is that the processes and assets themselves perform better because they have an expanded operating window (i.e., lower emissions and heat rate translates to being more reliable). The decisions that the cloud analytics support will be different and offer more upside because they will leverage these "better" assets. There is also a great deal to be gained on the cloud by leveraging the data and insights that Edge AI/ML applications provide.

The Holy Grail: Network Level Optimization

Finally, AI/ML pushes the boundaries of how processes or assets can be viewed as part of networks, with optimization performed at both the asset and network levels. We frequently find that processes, and even assets, are defined by human scope and ability to manage them.

Think about this scenario: a turbine can be optimized, but would the plant overall be better served by a different operating profile for the turbine? Maintenance can be optimized, but in light of immediate profit opportunities, is the better choice to deprioritize maintenance, make more money, and make up for the wear and tear down the line?

What does the future fold?

With more digital industrial companies leveraging an expanding, integrated AI/ML platform to drive network level optimization, we can now look to the future and ask new questions. Assuming that we solve the cybersecurity problem, can we automate and optimize the grid and generation as one big machine? Can we address inertia prediction, integrate renewables and enable consumer-level energy trading through blockchain? If we do, can we design better regulatory and market structures?

These are difficult questions, and we live in a constrained world. But 30 years ago, no one was controlling fuel air distribution in closed loop, and we are doing that in hundreds of plants today.

The most important thing is to find actions that drive value and that AI/ML can influence. Create affordable AI/ML applications that deliver stand-alone value and even more when integrated with other AI/ML applications. Then, keep doing it. There is a lot of value out there to capture.