Guided by multiphysics simulation, General Fusion reached a major milestone this year in its quest to bring fusion power to the commercial grid: successfully compressing a large-scale magnetized plasma with lithium using the world's first fusion demonstration machine.

Magnetized Target Fusion (MTF) power plants have the potential to produce significant amounts of energy with comparatively inexpensive technology and without releasing carbon emissions. In a General Fusion MTF machine, hydrogen plasma is injected into a liquid metal vessel formed inside the fusion machine. From there, an array of pistons compress and reshape the liquid metal vessel around the plasma, increasing the density and temperature of the plasma to fusion conditions — making fusion happen! It is a pulsed approach that repeats once per second in a commercial plant. The liquid metal wall of the vessel captures the energy of the neutrons, converts it to heat, and then carries it to a heat exchanger to create steam and ultimately produce electricity.

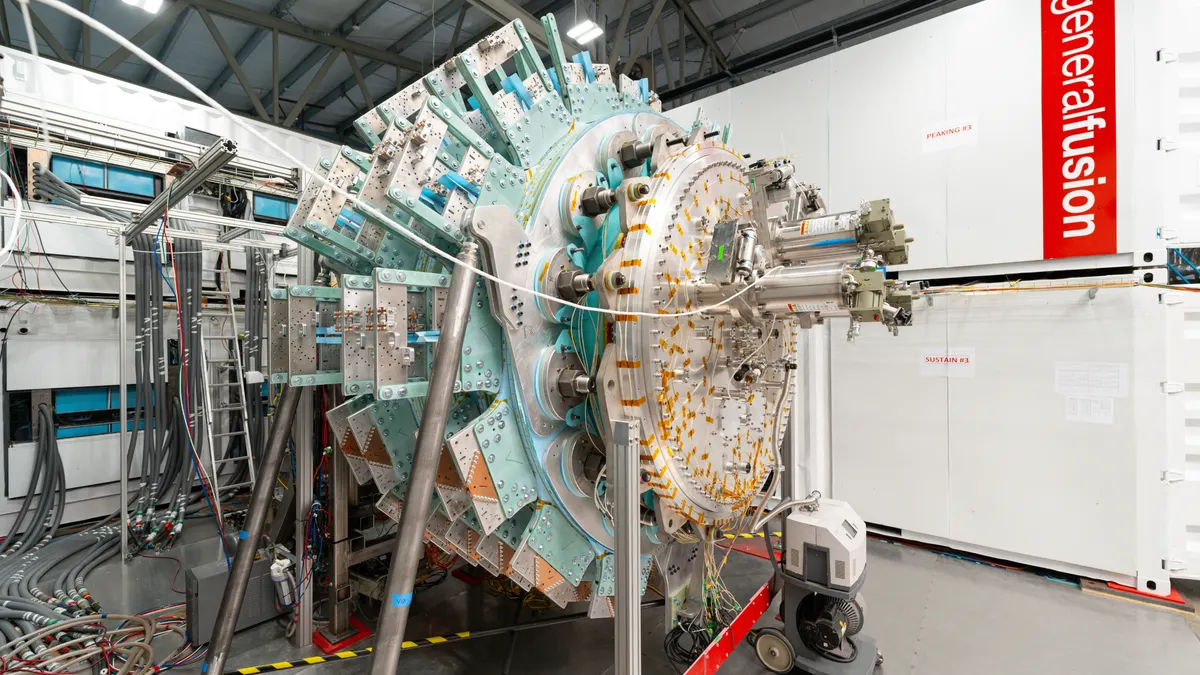

The engineers at General Fusion are using MTF to bring fusion power to the commercial power grid by the early to mid 2030s. This journey has reached multiple milestones within the last year, beginning in late 2024 with the construction of Lawson Machine 26 (LM26), General Fusion's large-scale fusion demonstration machine, which was built to de-risk the eventual commercial machine. Through the use of multiphysics simulation, General Fusion successfully designed and optimized LM26, which achieved "first plasma" in February 2025.

During the months that followed, the team used LM26 to form plasmas regularly, optimizing the machine's performance in preparation for its next goal — compressing plasmas to create fusion and heating from compression. In April 2025, General Fusion achieved this goal: Preliminary analysis of the first compression indicated that the ion temperature and density increased and the lithium liner successfully trapped the magnetic field, marking a major step toward the team's fusion-powered vision for the future.

The team at General Fusion assembling LM26.

Modeling Magnetomechanical Compression of a Solid Lithium Liner

LM26 was designed to target the key temperature thresholds of 1 keV, 10 keV, and the equivalent of scientific breakeven by compression of a solid lithium liner. With the COMSOL Multiphysics® software, the team was able to model and measure the internal effects to predict the performance of the LM26 design.

"When I joined General Fusion, looking at the type of challenges we were facing, I thought that COMSOL Multiphysics would be a great tool to add to our list of software," said Jean-Sebastien Dick, engineering analysis manager at General Fusion. "This is what got us to interact with Veryst Engineering, who are well-known experts in the field of multiphysics."

General Fusion’s partnership with Veryst Engineering, a consulting firm that specializes in highly nonlinear simulation and material modeling, was essential in the development of LM26. Sean Teller, a principal engineer at Veryst, worked alongside Dick to develop material models that enabled the team to accurately simulate the response of the lithium liner. This information was critical for accurate, predictive modeling of the LM26 liner trajectories, which enabled General Fusion to create and assemble LM26.

The LM26 geometry.

As Teller explained, "We used COMSOL Multiphysics simulation with integrated experimental plans and validation to enable the team at General Fusion to quickly iterate on designs of LM26. The predictive models are critical for achieving fusion conditions."

Different LM26 designs were able to be weighed simultaneously and in the same space in the COMSOL® software. Veryst and General Fusion used a time-dependent, fully coupled solver and automatic remeshing to capture the large deformation and pressures inside LM26.

"The framework of COMSOL has allowed us to incrementally build in complexity, build confidence in our design intentions, and avoid having to reiterate the design phases," Dick said. "We have not had to change any major parts of these experiments. They have always behaved as intended."

The plot shows the experimental data (square data points) as compared to the material model prediction (dashes).

The Future of Simulation and Fusion Power

Combining fully coupled multiphysics simulation with real-life experimentation was critical in the development of LM26. "We are no longer just looking at aerodynamics or fluid dynamics or structural dynamics one sector at a time; we are putting everything together," Dick said. "I believe that this is the way the future will go for simulation, because new innovations are very complex and require a lot of different physics to be involved together."

As the General Fusion team pushes fusion power to new heights, multiphysics simulation and fusion research will continue to be inextricably linked