In July, U.S. steelmaker Cleveland-Cliffs revealed plans to build an electrical distribution transformer plant on an idled industrial site in Weirton, West Virginia. The proposed project, which Cliffs said could eventually employ 600 union workers recently laid off from a neighboring facility, was a big enough deal to attract the state’s Republican governor to a press conference onsite.

Less than a year later, Cliffs abandoned the project as part of a wider shift away from what CEO Lourenco Goncalves called “non-core markets” on a May 7 investor call.

The decision highlighted ongoing challenges for a commercial electrical equipment supply chain that has yet to fully recover from the COVID-19 pandemic. On average, customers today wait three years for high-voltage transformers and one year for distribution transformers, said Adrienne Lotto, senior vice president of grid security, technical and operations services at the American Public Power Association. About 80% of the former and 40% to 50% of the latter are imported, according to Benjamin Boucher, a Wood Mackenzie senior data analyst focused on electrical supply chains.

Meanwhile, the National Electrical Manufacturers Association predicts 2% annual electricity demand growth through 2050. Given load growth expectations, fully reshoring transformer production could take years and cost many billions of dollars — if it’s even feasible, Boucher said.

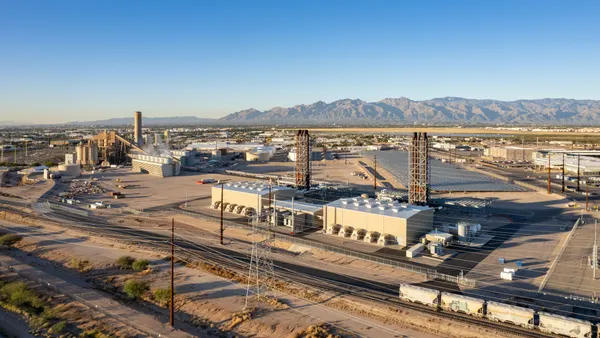

But after years of caution, the industry is giving it a go. Not long before Cliffs announced its now-abandoned West Virginia project, Siemens Energy said it would spend $150 million to build its first high-voltage U.S. transformer factory in North Carolina, where Pennsylvania-based PTT plans a $103 million expansion of an existing transformer manufacturing facility. Last month, MGM Transformers and VanTran Transformers opened a 430,000 square-foot plant in central Texas.

These and other capacity-boosting projects could help ease electrical equipment backlogs as U.S. utilities, data center operators and other energy-hungry customers look for components wherever they can.

Data centers and industrial growth driving demand

Data centers’ growing appetite for electrical equipment brought together DVM Power + Control and Mission Critical Group, which manufactures generators and electrical components at 10 U.S. sites.

Mission Critical Group acquired DVM earlier this year to expand its exposure to fast-growing markets for low- and medium-voltage electrical distribution equipment prized by data center customers, like switchgears, relay panels and power distribution units, MCG CEO Jeff Drees said in an interview.

DVM has served the IT market since the early 2010s, focusing initially on customers in the underserved Mid-Atlantic area, said Bob Ricci, DVM founder and president. Business really took off this decade thanks to a shift toward colocation — where customers rent space in shared, strategically located facilities — and the artificial intelligence boom, Ricci said.

“A year ago, Pennsylvania was not a big data center market,” he said. “Now, you have 10 or 15 developers looking at the Marcellus Shale region,” where abundant natural gas could eventually power multiple gigawatts of IT capacity. In April, a development group said it would build up to 4.5 GW of gas-fired generation to power a planned data center campus east of Pittsburgh.

The story is the same in other regions of the U.S. The Texas IT industry, for example, is “trying to do in five years what took Northern Virginia 35 years,” Drees said.

Ricci said DVM and MCG also see increased industrial demand from pharmaceutical manufacturing, another key Pennsylvania industry, and from the semiconductor and oil-and-gas industries. Those customers find themselves in competition with the utilities that serve them and with the energy developers and independent power producers driving the rapid U.S. renewables buildout.

“The explosive growth we’ve seen in renewables over the past five years has been a huge boost in demand for transformers,” Boucher said.

Utilities have also upped spending on transmission and especially distribution infrastructure since the early 2000s, with investment in distribution systems alone rising from $20 billion in 2003 to more than $50 billion in 2023, according to an Energy Information Administration analysis using 2023 dollars. Lately, at least some of that investment aims to get ahead of expected demand growth.

“What’s driving concern now is demand growth that electric utilities haven’t seen for many years,” Lotto said.

Notwithstanding policy-driven risks to renewables development from a hostile Congress and Trump administration, Boucher said the persistent transformer backlog put recent investments by companies like Siemens Energy, PTT, MGM and VanTran on solid footing for now.

“Given how much demand is outpacing supply, there’s not much risk of anyone being burned in the next two or three years,” he said.

Supply chain outlook

U.S. manufacturing investments don’t just increase the supply of transformers and other electrical components for utilities and other buyers, experts say. By siting final production closer to customers, they also shorten delivery timelines and mitigate supply chain uncertainty.

“Just being based in the United States adds a lot of value,” especially for customers that prize deployment speed above all else, Drees said.

A DVM competitor based in Asia might make the same component for 15% less, but overseas shipments can languish for months on ships or in ports, Ricci explained. Importers have a tendency to make “unrealistic promises” about how quickly they can fulfill customer orders, he said.

“You spent 15% less for a two-month delay, and then you have a very angry customer on your hands,” he said. “In our industry, if you keep your promises, customers don’t go anywhere else.”

President Trump’s tariffs, which have raised prices for thousands of imported products, provide another tailwind for suppliers that make electrical components in the United States. But for now, many buyers rely on imports, according to data from Wood Mackenzie. In 2024, Mexico supplied 39% of high-voltage transformer imports, which dwarf domestic alternatives in volume. Canada provided 20% of high-voltage switchgear imports. China supplied 54% of imported low-voltage transformers. South Korean and Brazilian manufacturers sell meaningful volumes of transformers into the U.S., too.

The U.S. also imports key electrical equipment inputs, like transformer cores and grain-oriented electrical steel, or GOES, the specialized conductive metal that makes them work. Japanese and South Korean GOES producers continue to sell into the U.S. despite a 25% tariff dating back to Trump’s first term, Boucher said. Cleveland-Cliffs is now the only onshore GOES producer, he added.

To avoid the tariff, Asian producers also sell GOES into Mexico and Canada, where local manufacturers shape it into transformer cores to be purchased by U.S. customers, a U.S. Commerce Department investigation found.

The U.S. may struggle to add GOES production capacity in the coming years unless prices rise, Boucher said. Making GOES is a “highly technical process” and the market for it is limited despite its importance for transformer manufacture, “so it depends on whether the supplier wants to take that risk,” he said.

That pattern can play out elsewhere in the supply chain. Until recently, Boucher said, the electrical equipment market’s boom-and-bust tendencies left suppliers wary of big bets on new capacity.

While demand seems more stable now amid sustained investment in renewable generation and AI data centers, recent capacity announcements “are really going to be a drop in the bucket next to what we need to be self-sufficient,” Boucher said.

But utilities and their manufacturing partners remain unsure of the shape and pace of U.S. load growth, Lotto cautioned.

“To the extent we can get more certainty around load growth, that will give the utilities more opportunities to do better planning and forecasting, which would give manufacturers more certainty around investment,” she said. “Demand signals are really important.”

NEMA wants to move things along. Earlier this year, it released detailed specifications for American-made distribution transformers and conductive wire and cable products, helping its members comply with Biden-era domestic content requirements.

More electrical component specifications could be on the way, said Spencer Pederson, NEMA senior vice president of public affairs.

Since 2018, electrical suppliers have invested $185 billion in U.S. manufacturing and imports from China have decreased 10%, spurred in part by Biden-era legislation that incentivized reshoring, Pederson said. To sustain that momentum, NEMA is pushing Congress to preserve the advanced manufacturing and energy property tax credits in a sweeping budget package that’s expected to face a final vote this summer.

“A lot of that $185 billion was low-hanging fruit,” Pederson said. “We are starting to get to the more difficult things to reshore.”

Correction: A previous version of this story misidentified the developer of a transformer factory in North Carolina. The developer is Siemens Energy.